How Advanced Technology Is Reshaping the Future of Prosthetics

In recent years, 3D printing has revolutionized the prosthetics industry, transforming what was once a purely manual and time-consuming process into a highly precise, flexible, and efficient digital solution. Prosthetic devices are no longer just mechanical replacements; they have become custom-made, integrated solutions designed individually for each user in terms of shape, weight, comfort, and function.

In this article, we explore how 3D printing is reshaping the future of prosthetic manufacturing, its key advantages, and how Qudra orthotics & prosthetics Lab utilizes this advanced technology to achieve optimal outcomes for its patients.

From Traditional Craftsmanship to Digital Precision

Traditionally, prosthetic manufacturing relied on manual measurements and plaster molds, followed by hand-crafted shaping using conventional materials such as resins and fiberglass. While these methods served patients for many years, they had major limitations—limited accuracy, excessive weight, long production times, and difficulty in post-fitting adjustments.

With the integration of digital technologies into medical engineering, 3D printing emerged as a transformative solution. It introduced a shift not only in manufacturing tools, but in the entire philosophy of prosthetic care—from standardized manual fabrication to fully personalized digital design.

Understanding 3D Printing Technology in Prosthetics

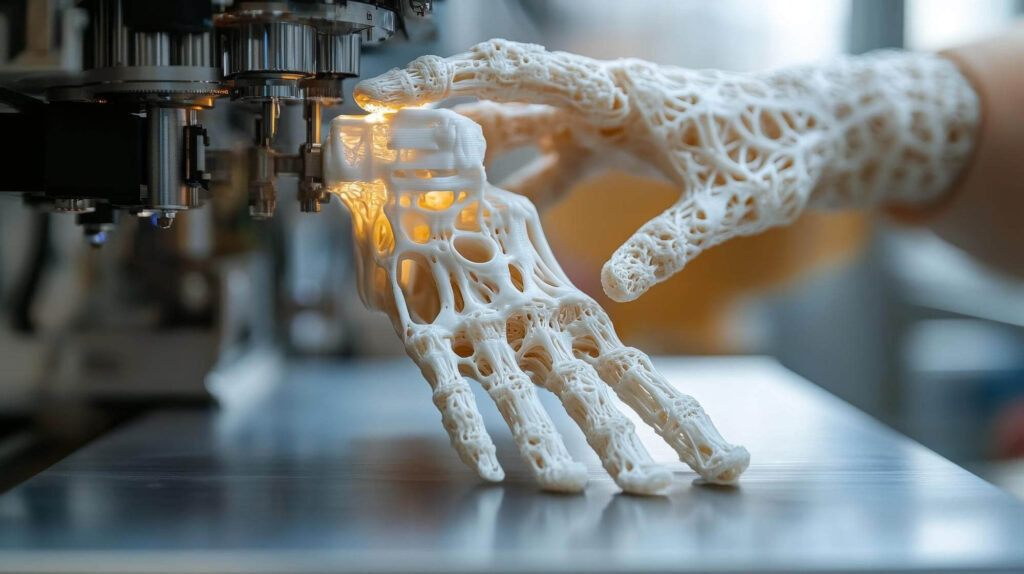

3D printing, also known as additive manufacturing, is based on building objects layer by layer from a digital 3D model. In prosthetic applications, the process begins with high-precision 3D scanning of the residual limb, creating an exact digital replica. This data is then refined using advanced CAD design software, where every functional and aesthetic detail is carefully engineered.

Once finalized, the design is sent to a 3D printer that produces the prosthetic component using specialized materials such as reinforced thermoplastics or carbon fiber composites, resulting in highly accurate, lightweight, and durable prosthetic structures.

This seamless integration of medicine, engineering, and digital technology ensures unmatched levels of precision and personalization.

The 3D Prosthetic Manufacturing Workflow

The production process follows a structured sequence to ensure optimal results:

1. Clinical Evaluation & 3D Scanning

The process begins with a comprehensive functional assessment of the patient followed by high-resolution 3D scanning of the residual limb. This ensures flawless anatomical matching and superior comfort.

2. Digital Custom Design

Engineers transform the scan data into a customized digital model, precisely adjusting weight distribution, support zones, and external appearance.

3. Material Selection

Material choice depends on function—lightweight flexible polymers for mobility, and skin-like textured materials for cosmetic prosthetics. Expert material selection is critical for performance and comfort.

4. Printing & Surface Finishing

The prosthetic is printed layer by layer, then refined through advanced finishing techniques to achieve a natural appearance and smooth, comfortable surface.

5. Fitting, Adjustment & Rehabilitation

Final fitting is followed by fine adjustments and specialized rehabilitation training to ensure full functional adaptation.

Key Benefits of 3D Printing in Prosthetic Care

This digital transformation has introduced significant advantages:

- Exceptional accuracy and anatomical compatibility

- Rapid production and reduced waiting time

- Lightweight structures without sacrificing strength

- Unlimited customization options in design, color, and texture

- Lower long-term costs through reduced material waste

- Easy digital modification and reprinting for future adjustments

Beyond Technology: Restoring Confidence and Quality of Life

The greatest impact of 3D printing lies in its human value. A comfortable, anatomically matched prosthesis enhances not only mobility but also psychological well-being, self-confidence, and independence. Patients regain the ability to engage in daily activities with dignity and freedom—reflecting the true mission of modern rehabilitation centers such as Qudra orthotics & prosthetics Lab.

How Qudra Integrates 3D Printing into Advanced Prosthetic Care

At Qudra orthotics & prosthetics Lab, 3D printing is a core component of an integrated clinical system. The center operates a dedicated digital design and medical printing unit, managed by highly trained engineers and technicians in collaboration with international technology partners.

The workflow includes:

- Detailed clinical assessment

- Advanced digital prosthetic design

- High-precision medical printing

- Professional fitting and rehabilitation

- Continuous post-fitting follow-up

This comprehensive model ensures high performance, superior comfort, rapid delivery, and long-term success.

Additionally, Qudra orthotics & prosthetics Lab actively supports the local development of 3D prosthetic technologies through academic partnerships, applied research, and continuous knowledge exchange—strengthening the regional medical manufacturing ecosystem.

The Future of 3D Printed Prosthetics

Despite remarkable progress, innovation continues. Ongoing challenges include:

- Developing advanced biocompatible materials

- Enhancing printer efficiency and speed

- Making technology more affordable and accessible

The future is highly promising with the integration of artificial intelligence, smart sensors, and neural control systems, allowing prosthetics to respond more naturally to human movement and neural signals.

The future of prosthetics is no longer about adapting humans to machines—it is about designing machines that adapt to humans.

Conclusion

What was once science fiction has now become a life-changing reality. 3D printing not only restores lost physical function—it restores identity, confidence, and independence.

Through its advanced technological integration, Qudra orthotics & prosthetics Lab continues to empower individuals to reclaim their lives safely and confidently — step by step, with prosthetics that are precise, lightweight, and designed specifically for them.

Experience the future of prosthetic care—designed precisely for you.

Discover how advanced 3D printing and personalized digital design can transform comfort, mobility, and confidence.

Contact Qudra Orthotics & Prosthetics Lab today to schedule a comprehensive digital evaluation and explore next-generation prosthetic solutions.